Yawara Iron: Forging the Spirit of Sport with Strength and Precision.

Fusing centuries of Japanese metalworking tradition with cutting-edge technology to craft elite athletic equipment and structures.

Request a Consultation

The Soul of Steel: Our Philosophy

At Yawara Iron, we believe every piece of metal has a story. Inspired by 'Yawara'—the principle of gentle strength in martial arts—we forge with both power and precision. Our workshop in Tokyo is a crucible where traditional techniques passed down through generations meet modern material science.

We don't just shape metal; we forge the future of athletic performance and resilience, creating components and structures that embody both artistry and uncompromising durability. Our commitment to excellence is as strong as the steel we work with.

Our Expert Services

Precision Forging

Creating high-integrity athletic components (e.g., bicycle frames, weightlifting bars) with superior strength-to-weight ratios, ensuring peak performance and longevity for every athlete.

Facility Metal Fabrication

Custom design and fabrication of architectural metalwork for dojos, gyms, and stadiums, from elegant entry gates to robust structural supports, built to inspire and endure.

Vintage Equipment Restoration

Meticulous repair and restoration of classic sports equipment, preserving its history while renewing its function and beauty for future generations to appreciate.

Specialized Welding

Applying advanced TIG and MIG welding techniques for high-stress applications in motorsports and extreme sports gear, where integrity is paramount and failure is not an option.

The Yawara Forging Process: From Concept to Creation

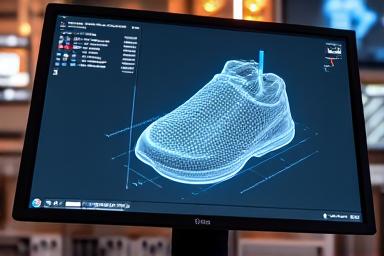

Consultation & Design

We begin with collaborative 3D modeling and analysis to translate your vision into a precise digital blueprint, ensuring every detail is captured.

Material Selection

Based on performance needs, we select the ideal alloy—from lightweight titanium to ultra-durable, high-carbon Japanese steel, optimized for your specific application.

Forging & Shaping

Our master smiths use a powerful combination of hydraulic presses and traditional hand-hammering to shape the metal at optimal temperatures, enhancing grain structure and strength.

Finishing & Quality Assurance

The piece is precision-milled, expertly heat-treated, and rigorously tested through various methods to ensure it meets our exacting standards of quality and resilience.

Project Showcase: Strength in Action

Kensei Project: Titanium Bike Frame

Category: Precision Forging

A bespoke titanium bicycle frame, meticulously forged for a discerning athlete, featuring subtle design cues reminiscent of a traditional samurai sword. Engineered for aerodynamic efficiency and unyielding durability.

Mushin Gate: Kendo Dojo Entrance

Category: Facility Metal Fabrication

A hand-forged iron gate for a prestigious kendo dojo, designed to embody the spirit of simplicity and strength ('Mushin'). Each curve and joint reflects traditional Japanese aesthetics.

1924 Olympic Saber Restoration

Category: Vintage Restoration

A painstaking restoration of a historical dueling saber believed to have been used in the 1924 Paris Olympics. Our experts brought it back to its original glory, preserving its heritage.

Advanced Technology

Our facility is equipped with state-of-the-art technology, including high-precision 5-axis CNC milling machines for intricate component finishing, and powerful Finite Element Analysis (FEA) software for meticulous stress simulation. We utilize laser-based material analysis to ensure the integrity of every alloy. This integrated approach allows us to achieve sub-millimeter tolerances and deliver unparalleled material integrity for every project, from concept to final product.

Sustainability in Metalwork

We are deeply committed to responsible manufacturing. Our innovative processes include advanced heat recapture systems from our high-temperature forges, significantly reducing energy consumption. We operate a comprehensive metal scrap recycling program, diverting waste from landfills, and meticulously source raw materials only from suppliers who adhere to strict environmental and ethical standards. At Yawara Iron, we firmly believe that superior strength should never come at the expense of our planet.

Partnership Inquiries

Start Your Project Journey

Have an innovative idea for athletic equipment? Need a detailed consultation or a precise quote for a custom metalwork project? Our team of skilled artisans and engineers is ready to help you bring your vision to life with precision and expertise. Fill out the comprehensive form below, and we guarantee a personalized response within two business days.

Visit or Connect Directly

Location: 7-15-2 Kyobashi, Chuo-ku, Tokyo, 104-0031, Japan

Phone: +81-3-5777-XXXX

Email: [email protected]

Business Hours: Monday - Friday, 9:00 AM - 6:00 PM (Japan Standard Time)